How to check if your hook is sharp or worn

10 min read

Let me tell you something most tackle companies don’t want you to hear - the vast majority of hooks coming straight out of packages aren’t nearly as sharp as they should be. And those premium hooks you’ve been fishing with for the last six months? They’re probably duller than a political debate.

The Fingernail Test: Still the Gold Standard

The simplest and most reliable test remains the good old fingernail test. Here’s how to do it properly:

- Hold the hook securely (a pair of hemostats works great).

- Gently drag the point across your thumbnail with very light pressure.

- A truly sharp hook will catch immediately without sliding.

- If it slides even slightly before grabbing, it’s not sharp enough.

But here’s the key most guides don’t mention - the direction matters. Drag perpendicular to your nail, not at an angle that might make a dull hook seem sharper than it is. And use the lightest pressure possible. If you need to press down to get it to catch, that hook’s not tournament-ready.

I’ve gone through entire tackle boxes testing hooks this way before major tournaments. Shocking how many “brand new” hooks fail this basic test.

Beyond the Fingernail: Advanced Testing Methods

The Paper Test

Hang a sheet of standard printer paper off the edge of a table. A properly sharpened hook should penetrate the paper with just the weight of the hook itself - no pushing required. This test reveals not just sharpness but also the hook’s point design efficacy.

I use this test mainly for larger hooks - 2/0 and up - where the fingernail test can be less revealing.

The Sound Test

This one sounds strange until you try it. Hold the hook by the eye and gently run the point across a soft piece of wood (a popsicle stick works great). A sharp hook creates a consistent scratching sound. A dull hook’s sound will be interrupted with skips and jumps.

I picked this trick up from an old Florida guide who could tell just by sound which hooks in his box needed attention.

The Light Test

Take your hook into bright sunlight or use a powerful flashlight. Rotate the point while looking directly at the tip. A sharp hook has a point so fine you can barely see it - it should disappear from view at certain angles. A dull or damaged hook will reflect light differently, showing a rounded or flattened surface.

This test saved my butt during a night tournament when I couldn’t feel the fingernail test as well as usual. The flashlight revealed hooks far duller than my tired fingers could detect.

Common Signs Your Hook Is Toast

After inspecting thousands of hooks over the years, here’s what I look for beyond basic sharpness:

-

Point Rollovers - The very tip bends slightly to one side, often from hitting rocks or hard structure. These hooks might still stick in your fingernail but will slide off fish lips.

-

Rust Spots - Even tiny spots indicate deterioration of the metal. The hook may still seem sharp but will be structurally compromised.

-

Gray or Whitish Appearance - This indicates the protective coating has worn off, meaning the hook is softer than when new and won’t hold its point.

-

Straightening - If the hook bend has opened even slightly from previous fish, retire it immediately. A hook that’s been stressed once will fail again.

I learned about point rollovers the hard way when fishing rocky shorelines for smallmouth. Hooks that passed the basic fingernail test were still missing fish because the points had subtle damage invisible to the naked eye but obvious under 5x magnification.

The Truth About Hook Materials and Coatings

Not all hooks are created equal, and understanding the materials helps you know what you’re dealing with:

High-carbon steel hooks are the standard. They sharpen easily but rust quickly if the coating is compromised.

Stainless steel hooks resist corrosion but are typically harder to sharpen properly and often don’t come as sharp from the factory.

Vanadium steel hooks offer the best of both worlds - they hold an edge and resist corrosion, but you’ll pay dearly for them.

As for coatings, here’s what decades of experience has taught me:

Black nickel isn’t just about looks - it’s generally more durable than standard bronze finishes.

Teflon and other non-stick coatings sound great in theory but often wear off quickly, leaving the hook vulnerable.

Tin coatings are common on budget hooks and provide minimal protection - expect rust after just one or two fishing trips.

I switched entirely to black nickel hooks in 2005 after noticing they maintained their sharpness through multiple fish catches compared to bronze hooks that seemed to dull faster.

How to Actually Sharpen a Hook Properly

Let’s be honest - most anglers do a terrible job sharpening hooks. They either oversharpen and weaken the point or don’t address the actual issues with the hook.

Here’s my field-tested method:

-

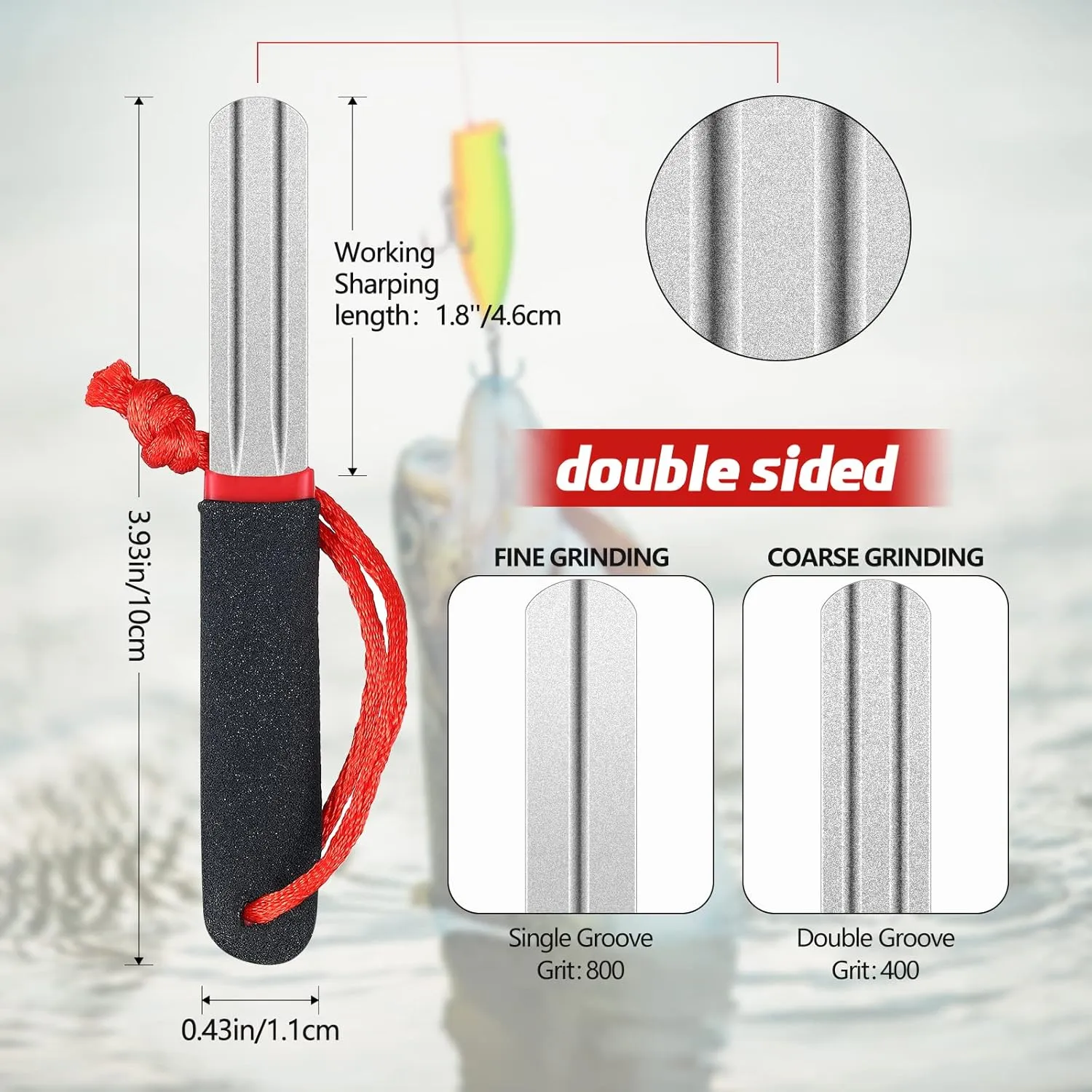

Get the right tools - Forget those generic “hook sharpeners” at the big box stores. Get a proper hook hone (I’ve used the same Luhr Jensen file for 15 years) or diamond files in fine and extra-fine grits.

-

Understand the anatomy - A hook has three surfaces that meet to form the point. All three need attention.

-

Use light pressure - Let the file do the work. Heavy pressure creates heat that can soften the metal.

-

Maintain the original angles - Don’t try to create new facets on the hook point.

-

Test frequently - Stop filing the moment the hook passes your sharpness test.

The biggest mistake I see? People filing the inside curve of the hook point, which actually makes it harder to penetrate. Focus on the outside and sides of the point.

The Inconvenient Truth About When to Replace vs. Sharpen

After resharpening thousands of hooks, here’s my honest assessment:

Resharpening works well 1-2 times on quality hooks. After that, you’re fighting a losing battle against metal fatigue and structural issues.

I rotate through my jigs and crankbaits, resharpening once before replacement. Anything beyond that is false economy - you’ll lose more fish than the few bucks saved on hooks.

For treble hooks? I rarely bother resharpening. The geometry is difficult to maintain properly, and replacements are relatively inexpensive. I simply keep a supply of quality replacement trebles in my boat.

Real-World Hook Management for Serious Anglers

Here’s how I actually handle hook maintenance after three decades on the water:

-

Pre-trip inspection - Every hook gets the fingernail test before it goes in my tackle box.

-

Post-fish check - After landing a good fish, I check that hook before casting again. This one simple habit has probably earned me thousands of dollars in tournaments.

-

End-of-day assessment - Any lure that saw heavy action gets inspected under my headlamp at day’s end.

-

Replacement schedule - Critical hooks (flipping jigs, primary tournament lures) get replaced far more frequently than casual fishing gear.

-

Storage matters - Hooks stored in humid conditions deteriorate even without use. Use silica packets in your tackle storage.

I keep a small Plano box with replacement hooks, a proper file, and small hemostats right on my front deck for quick access. Can’t tell you how many times this has saved a fishing day.

Species-Specific Considerations

Different fish demand different levels of hook sharpness and maintenance:

Trout and Panfish - Even slightly dull hooks will fail with these soft-mouthed species. Test before every trip.

Bass - Particularly Florida-strain largemouth have tough, bony mouths that destroy hook points quickly. Check after every fish.

Pike and Musky - Their teeth create microscopic serrations on your hooks. What feels sharp may actually have tiny “saw tooth” damage.

Saltwater Species - Salt accelerates corrosion dramatically. Rinse hooks in fresh water after every use and replace more frequently.

I learned this lesson fishing for redfish in Louisiana. Hooks that worked perfectly for bass were missing hooksets on reds with their harder, plate-like mouths. I now carry different hooks for different species.

Visual Inspection: Use Your Eyes (And Maybe a Magnifier)

Sometimes the simplest approach works best. Under good lighting, carefully examine your hook point. A sharp hook has a perfect point with no flattened areas, bends, or burrs.

For those of us whose eyes aren’t what they used to be (no shame in admitting it), a small magnifying glass can be incredibly helpful. I keep a pocket-sized one in my tackle box, and it’s revealed countless hooks that needed attention before I would have caught it otherwise.

Look specifically for:

- A perfectly tapered point

- No visible flattening at the tip

- No sideways bends or twists

- No rust or corrosion

The Cotton Ball Test: Surprisingly Revealing

This is a less common test, but it works wonderfully. Take a cotton ball and lightly drag your hook across it. A sharp hook will catch the cotton fibers easily and hang on when you lift it.

What’s great about this method is that it mimics what happens when a fish strikes - the hook needs to catch and penetrate soft tissue. If your hook can’t grab cotton fibers, it’s going to struggle with a fish’s mouth too.

When Technology Meets Tradition: Hook Sharpness Testers

For the gear lovers among us (I’ll raise my hand here), there are actually mechanical hook sharpness testers available. These devices measure the exact pressure needed for a hook to penetrate material, giving you a precise measurement of sharpness.

Are they necessary? Probably not for most weekend warriors. But for competitive anglers or guides whose livelihood depends on clients hooking fish, they provide consistency and confidence that’s hard to beat.

Prevention: Better Than Cure

Sharp hooks don’t stay that way by accident. A few preventative measures can extend the life and sharpness of your hooks:

- Store hooks properly to prevent contact with hard surfaces

- Rinse hooks with fresh water after saltwater use

- Consider hooks with protective coatings for corrosion resistance

- Replace hooks that have encountered rocks, gravel, or bones

I learned a great trick from an old-timer on my local lake - he keeps his favorite crankbaits hanging in his workshop with the hooks suspended in small containers of mineral oil. Prevents rust, keeps them sharp, and looks pretty cool too!

Different Hooks, Different Standards

Not all hooks need the same level of sharpness. The species you’re targeting should inform how sharp your hooks need to be.

For panfish with soft mouths, moderately sharp hooks work fine and are actually sometimes preferred to prevent tearing. But for species with tough, bony mouths like muskie or striped bass, you want needlepoint sharpness.

Similarly, the fishing technique matters. When bottom fishing where a fish might pick up your bait and move off before you detect the bite, razor-sharp hooks can lead to self-hooking. For reaction baits like crankbaits or topwater lures, maximum sharpness gives you the best chance of hooking up on the strike.

When to Replace Instead of Sharpen

While sharpening is great, sometimes replacement is the better option. Here’s when to consider swapping out those hooks:

- When the point is broken or severely bent

- If there’s significant rust or corrosion

- When the hook has been resharpened multiple times

- If the hook point has developed a “rolled” edge that’s difficult to fix

Quality hooks aren’t cheap, but they’re still less expensive than the memory of “the one that got away” because you tried to squeeze too much life out of a compromised hook.

The Final Point

At the end of the day, fishing success comes down to attention to detail. While we love discussing the latest rods, reels, and lures, sometimes it’s the smallest component that makes the biggest difference. The humble hook - that tiny piece of metal - is literally the point of connection between you and the fish.

So next time you’re preparing for a fishing trip or experiencing unexplained misses on the water, take a moment to check your hooks. That simple act might just be the difference between fishing and catching.

After all, in fishing as in life, it’s often the sharpest tool that gets the job done.